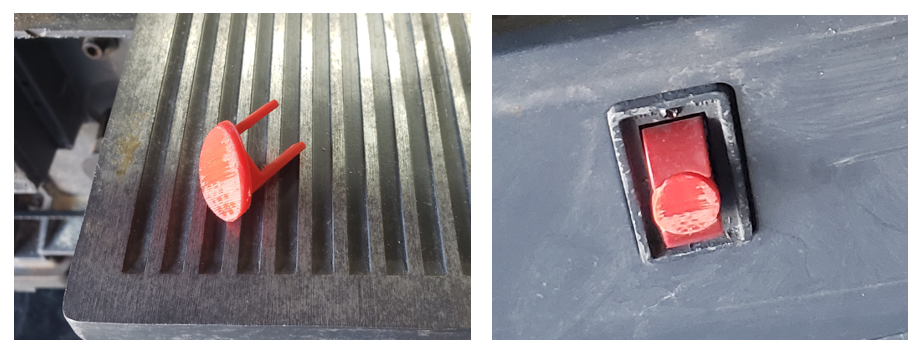

My compressor crapped out about a week ago. After I took the cover off, I discovered a circuit board inside with a DC motor. The fuse on the circuit board was blown. After making a trip to Lowe's to get 3A 1-1/4 inch AGC fuses, I replaced the fuse. When I powered the compressor it blew the fuse again.

I suspected a burned out motor, but didn't see any indication. I made sure the compressor was unplugged and removed the cover again. The small circuit board seemed simple enough, as it contained only a bridge rectifier and a capacitor and fuse.

I removed the screws holding the circuit board to the chassis and turned the board over to look.

I traced out the circuit, as shown below:

The input ac power is fused, then run to the power switch. From there the AC line goes through a 100 psi pressure limiter switch. After this the AC line and neutral are applied to a diode rectifier. The rectified DC is filtered by a small capacitor and then applied to the DC motor.

The motor resistance was 13 ohms which seemed reasonable. I clipped one of the wires to the motor to isolate the circuit from the motor. Then I used my multimeter in diode voltage mode to check the diode bridge. One of the arms of the diode bridge was shorted. The bridge is a KBPC610, which I found I could order 10 pieces from Amazon for $8.

When I received the replacement diode bridge, I soldered it in and tested the compressor, but it didn't work. After some troubleshooting I found that one of the AC input connections to the board had broken off under the insulation. After fixing this the compressor ran ok. I carefully spliced and insulated the wire I had cut to the motor. Then put everything back together, making sure that none of the wires was in danger of getting caught by the small axial fan that is under the cover.

I hope the air compressor will keep running. I bought it about 15 years ago at Harbor Freight in Houston.