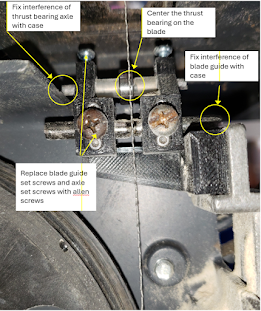

I installed the new lower guide into the Craftsman saw, as shown in the photo below. There were minor issues and one major issue as noted in the photo and the list below the photo.

click to enlarge

- There is interference between the left side of the thrust bearing axle and the case. This is easily fixed by cutting the ends of the axle down.

- There is possible interference between the right blade guide and the case. Fix by cutting the guide length down.

- Change all the set screws to Allen style headless screws. This will help reduce places to snag when installing the sawblade.

- The thrust bearing is not centered on the blade. For now I will install a shim under the lower blade guide support to move the guide over about 1 mm.

The saw runs fairly well, with some noise. Once I get the above issues on the lower guide fixed, I'll replace the wheel bushings with ball bearings, and replace the worn tires.

UPDATE:

I bought a bottom style 10-24 tap on Amazon.com for $3. It cleaned out the set screw holes very well. Now the set screws don't jam and it's easy to feel when the screw contacts the blade guide. I also shortened the thrust washer bearing axle and the two blade guides. Now there is no interference of those features with the case.

I printed a set of shims to use under the lower guide support to center the thrust bearing on the blade. The shims were nominally 1mm, 0.5mm, and 0.25mm thick. Upon actual 3D printing, each shim was 0.13mm or so larger than nominal. The 1mm and 0.5mm shims together seemed to center the blade on the bearing the best.

The photo below shows the shims after 3D printing.

click to enlarge

No comments:

Post a Comment