A blog of two hams.... Big brother is Mike, KA5VZE, in Tulsa, Oklahoma, little brother is Steve, KG5KCW, in Broken Arrow, Ok. Created for chatting about electronics projects, and maybe some woodworking and gardening too. Who knows?

Wednesday, June 28, 2023

3D printing: Garage wall bracket

Tuesday, June 20, 2023

SWR Meter (14) - Box rear panel for SWR coupler

I am modifying the rear panel of the 3D box to accomodate the shielded SWR directional coupler. The back panel is being modified into a box that holds the two sides of the coupler.

Rear view of modified panel:

SWR Meter (13) - 3D printed box parameterization fixed

I started over with the parameterization of the box. After watching a Youtube video on parameterizing hole patterns, I was able to figure out how to get the hole patterns to work correctly with the parameters. 3"W by 5"L by 2" H box is shown below. The hole pattern algorithm needs a starting offset distance from the edge of the panel to the first hole for each direction W, H, and L. Then an equation determines the number of holes and the interval in between:

The paramters for this box are shown below.

- boxH, boxL, boxW: parameters are the box outer dimensions

- thick1, thick2: parameters are panel thickness parameters

- ??hole: parameters are for the screw holes, clearance and tap

- offset?: parameters are the offset distances to the first hole for H, W, and L

- nscr?: parameters are the equations to determine the number of holes and interval between holes.

Thursday, June 15, 2023

SWR Meter (12) - 3D printed box parameterization problems.

Using Fusion 360, I have attempted to parameterize the design of the RF tight project box that I designed for the SWR meter. The parameters I've used are:

- width, length and height of the box

- thickness of the panels

- countersunk clearance hole parameters

- self tapping screw pilot hole paramters

- L: length of the box

- H: height of the box

- W: width of the box

Wednesday, June 14, 2023

SWR Meter (11): Sheet metal box progress

Continuing frorm SWR Meter (9) we have built the first prototype of a sheet metal box for the SWR meter. The box is made from 22 ga weldable steel for the bottom and 26 ga weldable steel for the top. Note that the holes have been drill for attaching the top to the bottom, The row of holes along the top are for fastening the top to the internal dividers. The inside dimension of the top is about 1 mm too wide. That's not bad but we still need to work on making predictable bends.

The photo below shows the interior of the box, with a 3D printer divider (green plastic) mounted to the botoom.

Monday, June 12, 2023

SWR Meter (10) - 3D printed project box design in Fusion 360

I tried another SWR project box design using 3D printing rather than a sheet metal box. The design philosophy is as follows:

- Use flat panels as the box components, no U shapes or L shapes.

- Use 0.113" (3mm) panels

- Use countersunk #2-28 self tapping screws to assemble the panels together.

- Use enough screws spaced close together to ensure no open cracks along the seams where the panels join.

- All inside surfaces should be flat to facilitate laying copper or aluminum tape on the inside surfaces.

- Copper tape on the inside surfaces should form a continous conductive surface inside the box to be RF tight.

The box has a few problems:

- There are a LOT of screws. I only installed every other screw.

- The Torx drive on the #2 screws doesn't really drive the screws well. The driver slips out of the screw head often.

- Driving the self tapping screws into the edges of the 3 mm thick panels tends to cause the panel surface to dimple.

Wednesday, May 24, 2023

Philmore PS123 Power Supply (6): PS123 in the box unit from ebay.com

I purchased a Philmore PS123 from ebay.com for \$10. The unit was still in the box with original one-page flyer that passes as the operator's manual. The unit's schematic was shown, but doesn't quite match the wiring in the cabinet. It's almost identical to the circuit I traced out and previously blogged about. The filter capacitor is 2200 uF, rather than 2000 uF as shown in the schematic. The schematic shows a single 1K resistor from the collector of TR1 to the anode of the zener diode. The actual circuit has a 5.6K resistor from the collector of TR1 to the negative side of the 500 uF capacitor, then a second 5.6K resistor from the negative side of the 500uF capacitor to anode of the zener diode.

A photo of the interior of the unit is shown below. Note there appears to be a splice in the line going from the diode bridge to the fuse.Monday, May 22, 2023

Sheet Metal Inventory and Gauge Table

SWR Meter (9) - Project box design in Fusion 360

Friday, May 19, 2023

SWR Meter (8) - Project box

I am going to make the SWR meter enclosure out of sheet metal, and do the drafting in Fusion 360.

The plan for the enclosure is shown below: There needs to be a conducting shield between the tandem coupler and the log amp board. I'll use bulkhead mounted SMA connectors to feed the RF signals. I'll also put a shield between the detector board and the MCU/Display section. A 9V battery will go in the MCU section. Front panel controls will be a small battery switch, and a cutout for the OLED display.

Wednesday, May 17, 2023

Philmore PS123 Power Supply (5): Counterfeit regulators from China!

I wanted to be able to operate at 13.8V @ 2 amps continuously. For testing I bought a 15 ohm 10W resistor and two 4 ohm 20W resistors which I put in series to make an 8 ohm 20W resistor. The resulting currents at 13.8V should be 0.92A and 1.73A respectively.

Saturday, May 13, 2023

Philmore PS123 Power Supply (4): Adding adapter bracket

Saturday, May 6, 2023

SWR Meter (7): Test results of log amp detector

I ran tests on the response of the SWR detector PCB. Everything appears to function well. The response graph is shown below

click to enlarge

- P is the power on the load

- R is the load resistance (50 ohm)

- N is the number of turns on the current transformer of the coupler. (20)

Monday, May 1, 2023

40 meter NE602 DC RX -- 2023 version

At the request of KA5VZE, AKA "my big brother", I am going to make a replica of my original 1987 "NE602 40 meter RX". I covered the back story for my 1987 version in the immediately preceding blog post.

I have transferred the original design into a KiCad project and produced a new PCB layout on the same size 1.5" by 2" board. The details are shown below. I will order the boards from PCBWAY this week.

The original schematic is shown below. Except for the trimmer capacitors, all parts can still be obtained for the RX. (I guess from 1987 to 2023 makes the original project 35 years ago. Where did the time go?)

40 meter DC NE602 RX (2): Background

Link to first post about 40m NE602 DC RX

The original 40m DC RX was built to evaluate the NE602 mixer circuit. This was 1987 and I received a free sample of the NE602 on a blister card. It looked very useful, because it had the oscillator and double balance mixer all in one chip. I quickly learned that NE602 overloaded very easily but I still built a receiver up just for fun. draft article submission from 1987

Here's a photo of the original 1987 NE602 RX. It was housed in a Radio Shack cabinet, using a vernier dial for tuning, and volume and phone connections on the front panel. The 9V battery was inside the cabinet, and the antenna connection was through an RCA phono connector through the back panel.

Friday, April 28, 2023

SWR Meter (6): PCB populated, ready for testing.

I have populated the SWR detector PCB. The 0603 capacitors and resistors are about the size of sesame seeds and require a lot of care to install. With a little practice it seemed I was able to solder them to the board fairly well.

I set out a white paper napkin to hold the parts before soldering. The white napkin has good contrast with the tiny parts so they are easier to see and handle. I used a small Ungar Princess soldering iron with a very sharp point. I pair of tweezer is necessary to pickup and position the parts. I used ultrafine 0.3 mm diameter solder. To solder a 0603 part on the board, first solder a small dab of solder on one of the pads. Pick up the part with the tweezers and place it in position, one end on top of pad with the small dab of solder, the other end of the parts goes on the other unsoldered pad. Heat the soldered pad until the solder melts, then continue until the part itself heats up and wets with solder. The part will self-center on the soldered pad. After letting the pad cool. Solder the other pad to the part.

I tested the voltage regulator on the board. It produced 5V whenever the input voltage exceeded 6.5 volts.

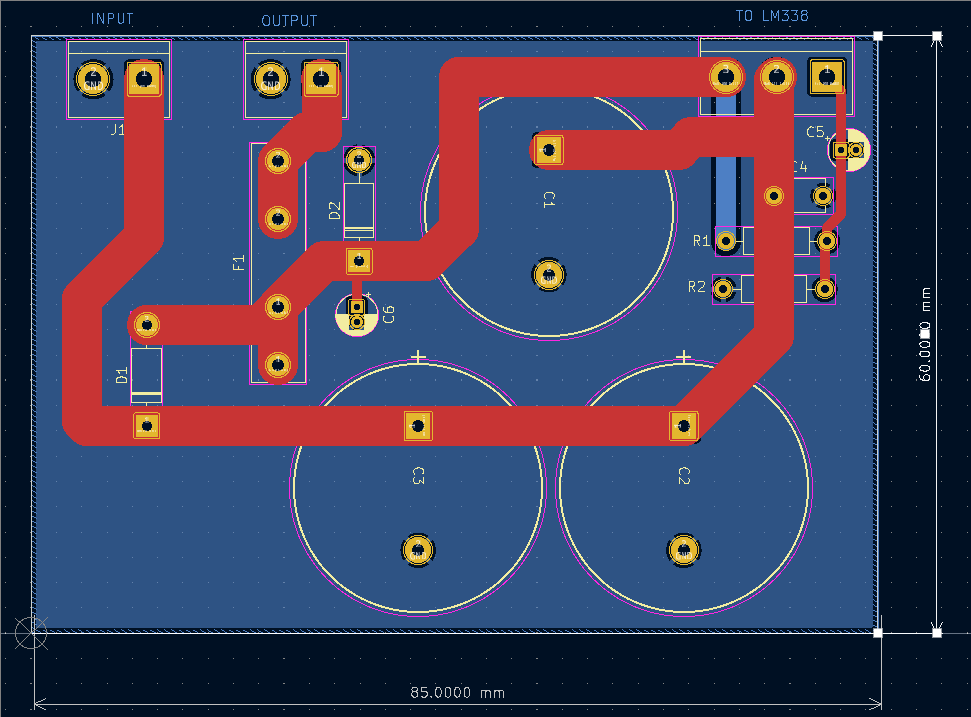

Philmore PS123 Power Supply (3): LM338 controller circuit and PCB

Until I get some more information to restore the Philmore PS123 power supply, I'm going to install a modern controller circuit in it and use it on my bench. The circuit is shown below.

I got the input filter capacitors at Affiliated Electronics in Tulsa. The combined capacitance is 9900 uF, which might cause some current inrush problems. My measurements on the winding resistance of the transformer indicates the inrush currents will be about 30 amps on the secondary, and 5 amps on the primary mains circuit. D1 and D2 are transient protection for the LM338. The LM338 controls for a 1.25 volt reference voltage from Vo to the ADJ terminal. The R1-R2 voltage divider is designed so that when the 1.25 volts appears (across R1) the voltage across R1-R2 in series (the output voltage) will be 12 volts. This is a straightforward circuit and is close to what is recommended in the LM338 datasheet.Thursday, April 27, 2023

Philmore PS123 Power Supply (2): description of unit as found

I continue to work on the Philmore 12V Power Supply. Below is a photo of the inside of the unit. I've indicated where the diode bridge is connected directly to the output positive binding post of the unit. You can see the mounting location of the TO-3 pass transistor on the back of the chassis behind the transformer. A small circuit board, not shown, mounts on the floor of the chassis to the left of the transformer.

The top and bottom view of the control PCB are shown below.

https://youtu.be/5IpG66imsn8

SWR Meter (5): PCB arrives from PCBWAY!

The circuit boards for the SWR project came in. Click to enlarge.

I will start work populating the board tonight.